Reflow soldering systems 551.10, 551.15 and 551.19

The soldering system 551.10 is a new development made by SEF and combines the competence of more than 30 years in the manufacturing of reflow ovens with modern requirements regarding usability, low power consumption and interfaces for the communication with other devices.

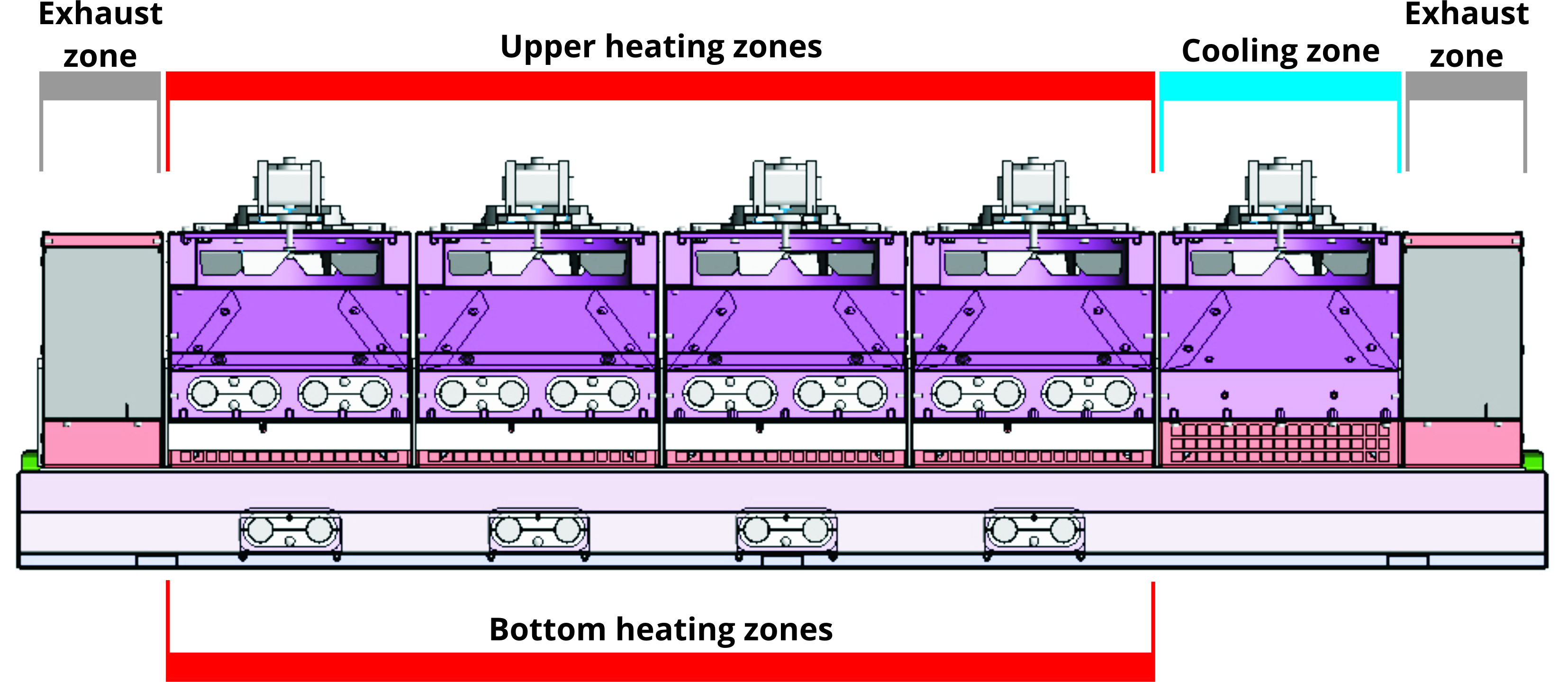

The basic system is designed as a desk top model and is equipped with eight heating zones, 4 upper and 4 bottom zones.The heating zones emit convection heat with the help of hot air fans. The upper part of the heating chamber contains additionally a cooling zone and an exhaust hood at the inlet area as well as at the outlet area.

The transport of the PCBs follows via a mesh belt. The operation of the soldering system is done with the help of a modern 7” touch panel. A 1-channel temperature profiler is integrated to check the soldering profile. The necessary thermocouple is included in the delivery.

Special version 551.15:

Here the cooling zone will be replaced by an additional heating zone so that the oven has 5 upper and 5 bottom heating zones. The cooling takes place by fans which will be mounted at the machine hood above the outlet area.

Technical data 551.10 551.19

Length: 2010 mm 3106 mm

Width: 790 mm 850 mm

Height:

- - incl. light pole550 mm

710 mm1270 mm

1432,50 mm

Weight: 190 kg 474 kg

Usable working width: 405 mm 405 mm

Active heating chamber

length:850 mm up to 2125 mm

Inlet height: 45 mm 45 mm

Conveyor speed:

- - typical15 cm/min – 90 cm/min

20 cm/min15 cm/min – 90 cm/min

45 cm/min

Heating power: max. 12 kW max. 21 kW

Connection values: 3 x 230/400 VAC/N/PE 50 Hz

with 16 A CEECON connector3 x 230/400 VAC/N/PE 50 Hz

with 32 A CEECON connector

Operation: 7“ Touchpanel 7“ Touchpanel

For more informations please read our product flyer: 551.10,15+19_EN